As a prominent advanced technology in the field of modern metal processing, laser tube cutting machines are widely used in cutting standard metal tubes and profiles, as well as special-shaped tubes, showing many impressive processes and advantages. The following will explore in depth the process of laser tube cutting machines and their advantages in tube cutting.

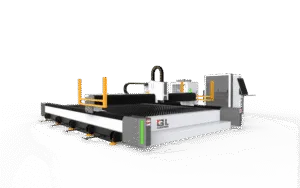

First, laser tube cutting machines can cut standard metal tubes and profiles with high precision. Using advanced laser technology, laser tube cutting machines can achieve micron-level cutting accuracy, ensuring that the edges of cut metal tubes or profiles are smooth and accurate. This advantage makes laser tube cutting machines widely used in fields that require high-precision processing, such as electronics, aerospace, and automobile manufacturing.

Secondly, the cut of laser tube cutting machines is smooth, burr-free, and has minimal material loss. Laser tube cutting machines use the high energy density of the laser beam to locally heat and melt the metal tube, and then quickly remove the molten metal by gas purging, thereby forming a flat and neat cut. This feature not only reduces the waste of materials, but also avoids the need for secondary processing of the cut in subsequent processing links.

Third, the laser tube cutting machine adopts non-contact processing, with a very small heat-affected zone and almost no deformation. Compared with traditional processing methods, the laser tube cutting machine does not directly contact the metal material during the cutting process, avoiding deformation and deformation caused by contact. This is quite advantageous for applications that need to maintain the accuracy of the workpiece shape, especially in the production process of precision parts and components.

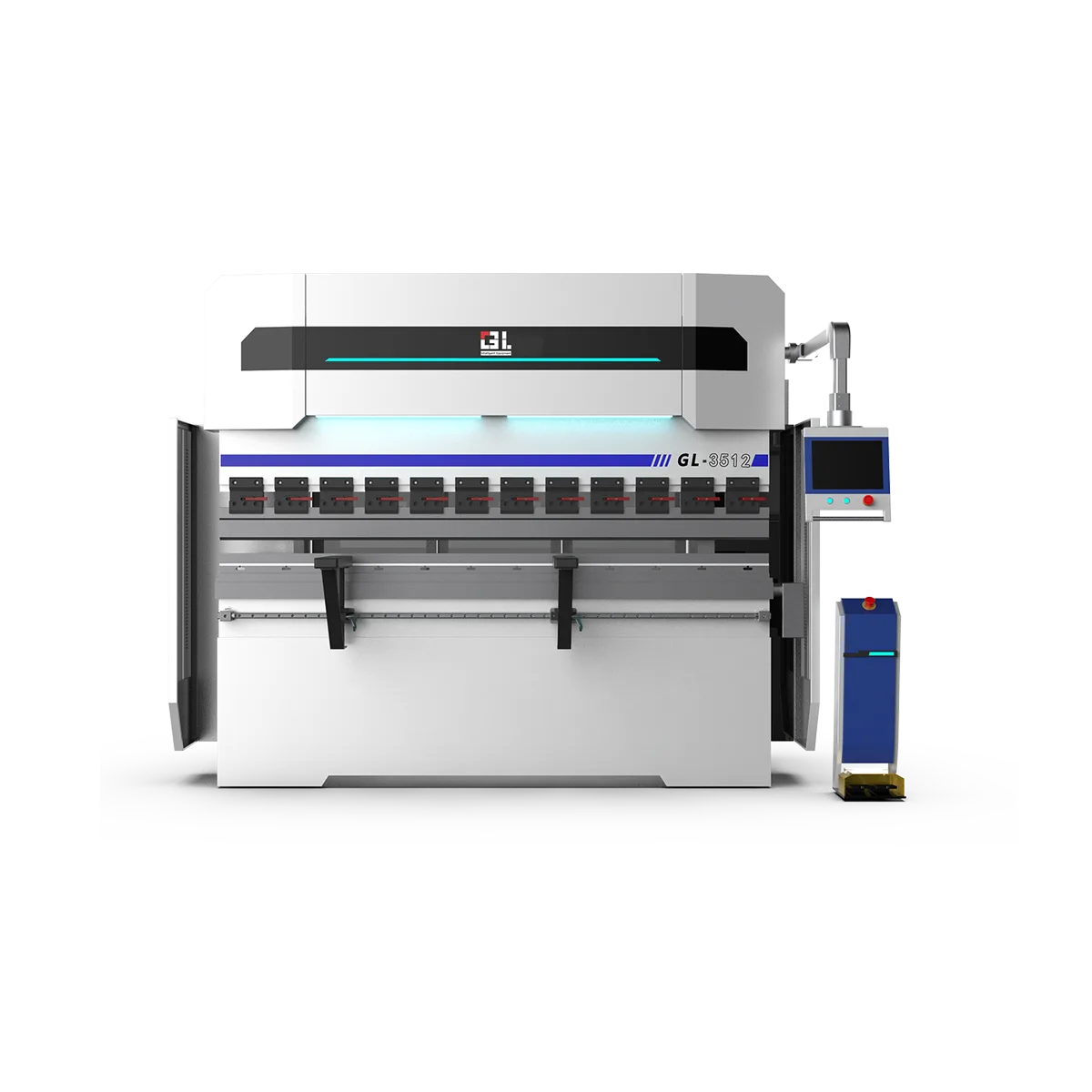

Fourth, the laser tube cutting machine has high cutting efficiency and can achieve mass production. The laser tube cutting machine adopts an automated control system, which can achieve precise control of cutting parameters, thereby improving cutting efficiency and reducing production costs. This makes the laser tube cutting machine an ideal choice for mass production and large-scale manufacturing.

Finally, the laser tube cutting machine has good flexibility. Using a professional CNC system, the laser tube cutting machine can change or replace the cutting mode of the product at any time, adapt to metal tubes and profiles of different shapes and sizes, and realize flexible adjustment of the production line.

In general, laser tube cutting machines, with their advantages of high precision, smooth cuts, non-contact processing, high efficiency and good flexibility, not only meet the needs of today’s metal processing field for high-quality and high-efficiency production, but also play an important role in promoting the intelligence and automation of industrial manufacturing. With the continuous development and innovation of laser technology, laser tube cutting machines will continue to show their strong application potential in various fields.