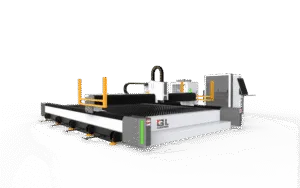

The laser tube cutting machine industry has experienced significant growth in recent years, driven by advancements in automation, precision manufacturing, and the rising demand for efficient metal processing solutions. These machines, which utilize high-powered lasers to cut tubes and profiles with exceptional accuracy, have become essential in industries such as automotive, aerospace, construction, and furniture manufacturing. The ability to handle complex geometries, reduce material waste, and integrate with digital systems has made laser tube cutting a preferred technology over traditional methods like sawing or milling.

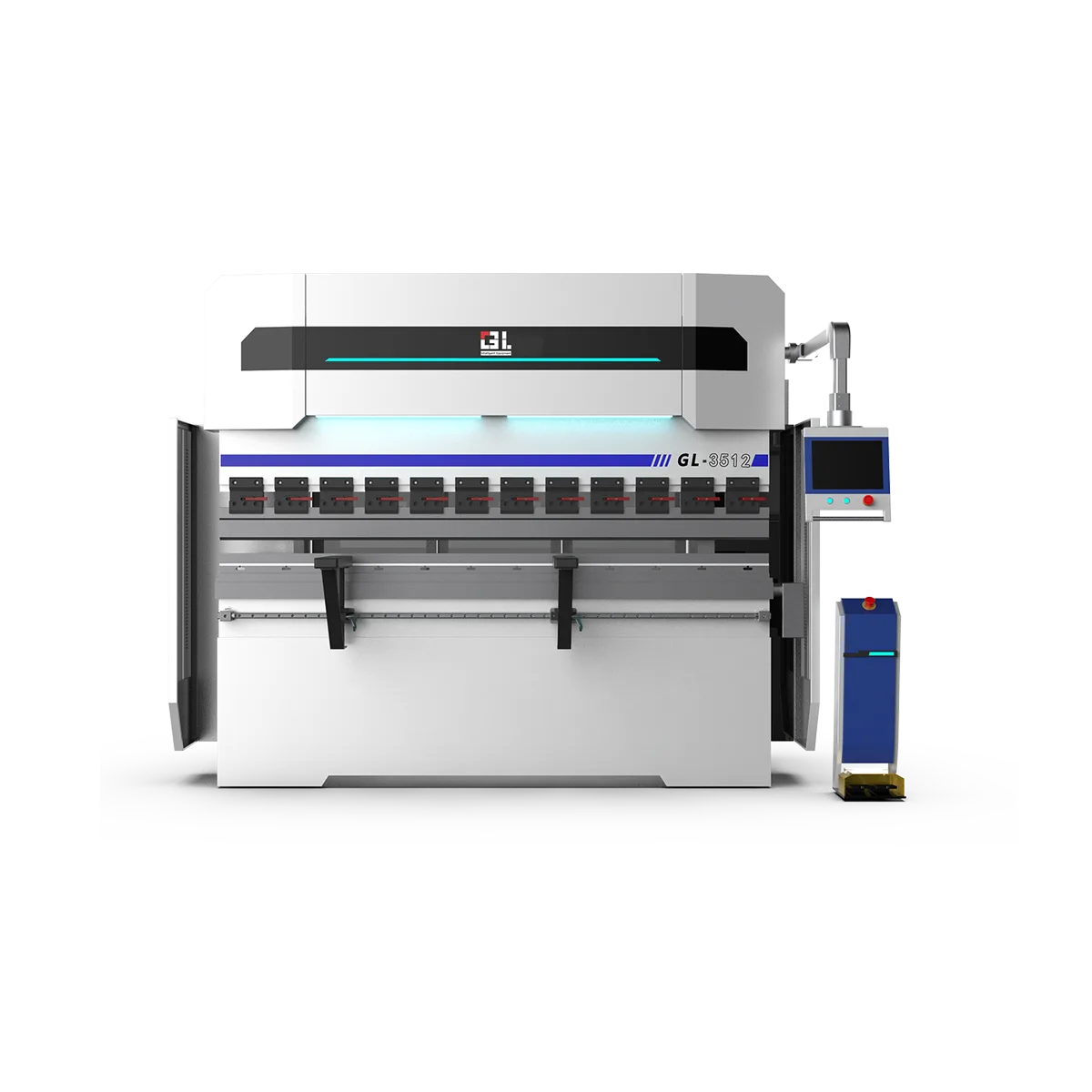

Technological innovation is a key factor propelling the industry forward. Modern laser tube cutting machines now feature advanced capabilities such as bevel cutting, multi-axis processing, and seamless integration with factory MES (Manufacturing Execution Systems) for real-time monitoring and automation. Companies like Guanli have further enhanced the market by producing proprietary components, such as custom chucks, which address common issues like precision deviation and weak clamping, thus improving overall performance. Additionally, the push toward Industry 4.0 has led to the development of unmanned workshops, where laser cutting systems are paired with robotic handling and intelligent material management to boost efficiency and reduce labor costs.

Market demand is also a driving force, as industries increasingly require high-speed, high-precision solutions to meet tight production schedules. The Asia-Pacific region, particularly China, has emerged as a major hub for laser tube cutting machine manufacturing, fueled by rapid industrialization and infrastructure development. Meanwhile, environmental concerns are encouraging manufacturers to adopt laser cutting for its minimal waste and energy-efficient processes. However, challenges such as high initial costs and the need for skilled operators remain. Overall, the laser tube cutting machine industry is poised for continued expansion, supported by technological advancements and growing industrial applications.